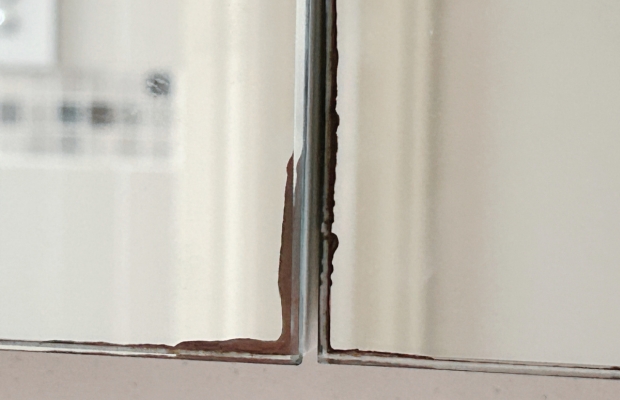

What is Mirror Edge Creep?

Mirror edge creep, also known as desilvering, is the gradual deterioration of a mirror’s reflective coating, typically starting at the edges. It appears as unsightly black or darkened areas that slowly spread, diminishing the mirror’s clarity and overall look. This issue is particularly problematic in high-moisture areas like kitchens, bathrooms, and laundries, where steam, water splashes, and cleaning chemicals can easily reach the edges of traditional mirrored splashbacks.

Why Does Mirror Edge Creep Occur?

Mirror edge creep happens when the protective layers on the back of a mirror are compromised. This allows moisture and other environmental elements to reach the reflective silver coating, causing it to oxidise and lose its shine.

Major Causes of Mirror Edge Creep:

- Moisture Exposure: In kitchens, bathrooms, powder rooms and laundries, steam and water splashes are unavoidable. Moisture can seep in and cause the silver backing to oxidise, leading to edge creep.

- Improper Cleaning Methods: Spraying cleaning solutions directly onto a mirror/splashback can cause liquids to run down and pool at the edges, penetrating the protective layers. To avoid this, always spray the cleaner onto a cloth first before wiping the surface.

- Poor Installation Techniques: Using adhesives with acidic components can compromise the mirror’s protective layers.

- Poor Quality Components in Manufacturing: Mirrors made with low-quality silver, inadequate protective coatings, or subpar backing materials are more prone to edge creep. Cheaper manufacturing processes may cut corners on the protective layers, making the mirror more vulnerable to moisture and oxidation. Investing in high-quality, well constructed mirrors/splashbacks can significantly reduce the risk of edge creep.

- Age and Wear: Even high-quality mirrors are subject to natural wear and tear over time. Exposure to environmental factors can gradually degrade the protective coatings.

Traditional Mirrors

Traditional mirrors use copper sulphate coatings that are prone to corrosion because copper reacts easily to air and moisture. These mirrors typically show signs of edge creep within 12-24 months. In contrast

Copper Free Mirror

Copper-free mirrors are manufactured using a two-coat paint process with a low-lead or lead-free solution, making them three times more resistant to corrosion than traditional mirrors. However, they are still susceptible to edge creep over time.

MirrorMax

MirrorMax is created using an advanced magnetron sputter coating process to produce a high-quality and durable product. This innovative fabrication method ensures long-lasting clarity and superior moisture resistance, preventing water and humidity from reaching the reflective coating.

Maintaining Your Mirror

Proper care will allow your mirror to last as long as possible, whether it is copper-free or not. It is recommended to clean your mirror following the Civic Mirror Cleaning Guide.

Download printable version

For more information please get in touch!